Tradition blended with the future - a recipe for success.

1785 en

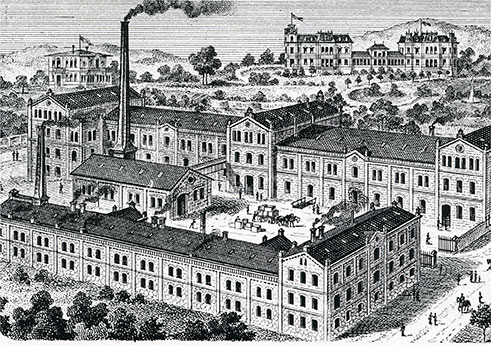

Stephan Witte & Co., Iserlohn, Stephanstrasse, contemporary lithograph, ca. 1864

1785

Conrad von der Becke founded a needle and pin factory in 1785 in Iserlohn, central Germany, and this was taken over soon afterwards by Johann Hermann Witte. This formed the foundation of the successful WITTE history – and with it, the KIRCHHOFF Group that developed from it.

1805 en

Commercial Counsellor Johann Stephan Caspar Dietrich Witte, ca. 1800

1805

His son, Stephan Witte, took over the management of the business in 1805, together with Franz Hermann Herbers, a professional tailor. Herbers had knowledge of the market's needs, Witte knew the production processes. Within a short time, annual production was up to ten million needles and pins.

1844-1845 en

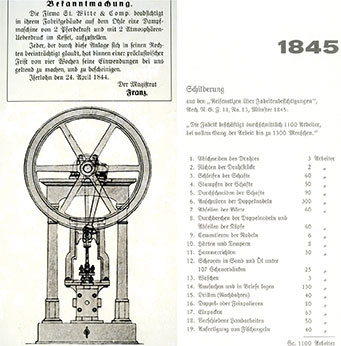

Announcement dated 24 April 1844 about a two horse-power steam engine for the Stephan Witte & Co. factory building.

Documentation showing the number of employees at Stephan Witte & Co. in the various production units, 1845

1844-1845

But only twenty years further down the line, the needle and pin-making industry in Iserlohn threatened to collapse. English companies were flooding the world market with their machine-made needles and pins and a quality hitherto unseen in this market.

Stephan's son, Hermann Witte, analysed a number of production methods and then promoted mechanisation in the family firm using machines developed specifically for WITTE. In only a few years, WITTE became, once again, one of the leading needle and pin producers with volumes of two million needles and pins a day.

1855 en

Statutes of the health and welfare association of Stephan Witte & Co., 1855

1855

Company records show that WITTE employed 1100-1200 staff at the time Stephan Witte founded a health and welfare association for WITTE employees in 1845, 28 years before Otto von Bismarck, the German Chancellor, introduced a law compelling their creation.

1864 en

Employees of Stephan Witte & Co. in front of the grinding mill and mill works, 1887

1864

Since world demand for German needles and pins was booming, WITTE founded a new factory in 1864 on the edge of the town, driven exclusively by steam power with overhead transmission gears.

1894 en

Public announcement about the opening of the Iserlohn press and stamping works of Stephan Witte & Co., 1894

1894

A new business division was in the making. In 1894, on the initiative of Friedrich Kirchhoff, who had worked his way up from assistant clerk to joint owner of the company within 15 years, a new press and punching plant was erected. Intended as a risk compensation exercise during the world recession at the end of the 19th century, it was the greatest commercial venture undertaken in the history of the company that already spanned over 100 years. Factories making locomotives and railway wagons, the mining and automotive industries all recognised the benefits of pressed sheet steel. WITTE was ahead of its time and opened the door to a profitable future-orientated chapter in industrial technology.

1914 en

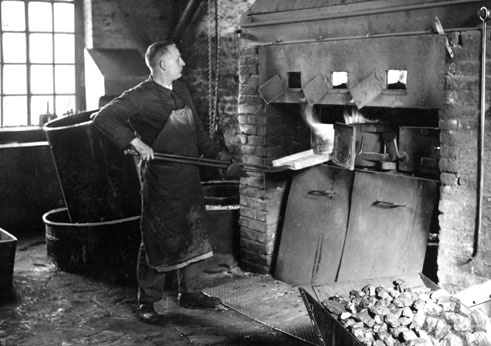

Needle manufacture, hardening shop, ca. 1900

1914

With the outbreak of World War I in 1914, the export-based needle and pin-making industry's chief market collapsed. After the end of the war, the industry took some time to recover. The heyday of needle and pin-making had effectively come to an end with the advent of the machine-based of garments.

1925 en

um 1925

General representative of Stephan Witte for China with his son, surrounded by Chinese wholesale merchants, ca. 1925

1945 en

Dr. h.c. Friedrich Kirchhoff with his 17 grandchildren, Jochen Friedrich Kirchhoff to the right of "Opapa" (grandfather) sitting on the wall with a pageboy haircut, ca. 1930

1945

In 1945, at the end of World War II, WITTE's press factory was close to being closed down for a period. However, WITTE received a production permit for essential products such as parts for coal mining machinery, wagon parts for railways, wheelbarrows for construction workers and frying pans for household use. The demand for needles and pins was also on the increase again. With monthly outputs of up to 60 million sewing needles, darning needles and special needles for the trades, this traditional manufacturing sector was entering its final golden age. At the same time, WITTE extended its range of products to include steel heating boilers and radiators for hot-water central heating systems and took advantage of the valuable know-how of the trained pin and needle makers, and its machinery from the needle and pin-making business, to develop a completely new product range: screwdrivers for industry, the trades and DIY amateurs.

1955 en

Screwdriver brochure, 1955–1956

promotional articles "Little gems", 1955–1959

1955

In 1955, Dr Fritz Kirchhoff introduced his son, Dr Jochen Friedrich Kirchhoff (Engineering), as a joint owner of the company. After 170 years, the needle and pin-making side of the business was finally closed down. Besides the sheet-metal pressing business, the newly created business areas of handtools and heating technology took on increasing importance in the ensuing years. The manufacture of screwdrivers was soon extended to no less than 1000 different products.

1980 en

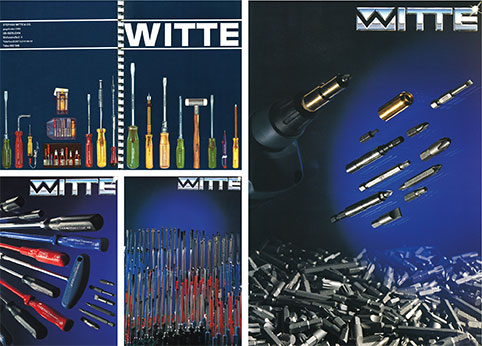

1980

In 1980, WITTE Tools started manufacturing insert bits. With a daily production volume of more than 20,000 screwdrivers, WITTE was already up among the best established manufacturers in Europe.

1981 en

1981

In 1981, the company span off the heating technology side of the business to concentrate on the construction of a new press shop for automotive components. On a plot of land covering around 100,000 m², and with a production area of 40,000 m², there was ample space for additional capacity for automotive parts and for expanding the machinery available to meet future requirements.

1986 en

Screwdriver brochure, 1968

Brochure of the range, 1989

Poster "flying bits", 1989

1986

In 1986, the increasingly successful WITTE Tools division added a new production facility in the adjacent town of Hagen, offering over 10,000 m² of shop floor space on a plot of land covering 60,000 m².

1990 und 1992 en

1990 - 1992

In 1990 and 1992, two sons of Dr Jochen Friedrich Kirchhoff, Arndt Günter Kirchhoff (Business Administration and Engineering) and Jürgen Wolfgang Kirchhoff (Engineering) joined the KIRCHHOFF Group as Managing Directors. In 1994, the Kirchhoff Group invested in the field of environmental and waste disposal logistics. The second son of Dr Jochen Friedrich Kirchhoff, Johannes Friedrich Kirchhoff (Engineering and Dr. rer. pol.), took on the task of managing the newly founded KIRCHHOFF Ecotec division.

1991 en

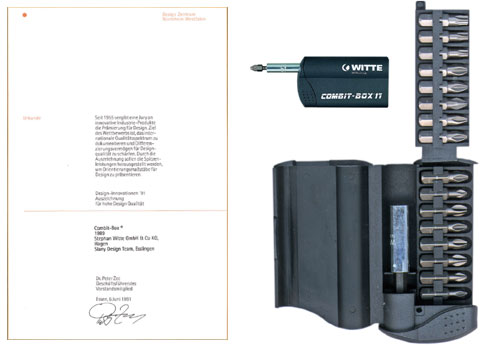

1991

The WITTE Combit-Box is honoured with the "Design Innovation '91" award by the Design Centre North-Rhine Westphalia.

1998 en

1998

A further award followed. PROTOP® screwdriver (right) and the Combit-Box 17® (left) are honoured with the International Design Award by the Design Centre Stuttgart.

2001 en

2001

WITTE receives the red dot: product design award for the PROTOP T-bar.

2006 en

The latest division to be added to the KIRCHHOFF Group was founded in 2006: KIRCHHOFF Mobility, a leading supplier of vehicle adaptations for individuals with mobility difficulties.

2006

HEUTE en

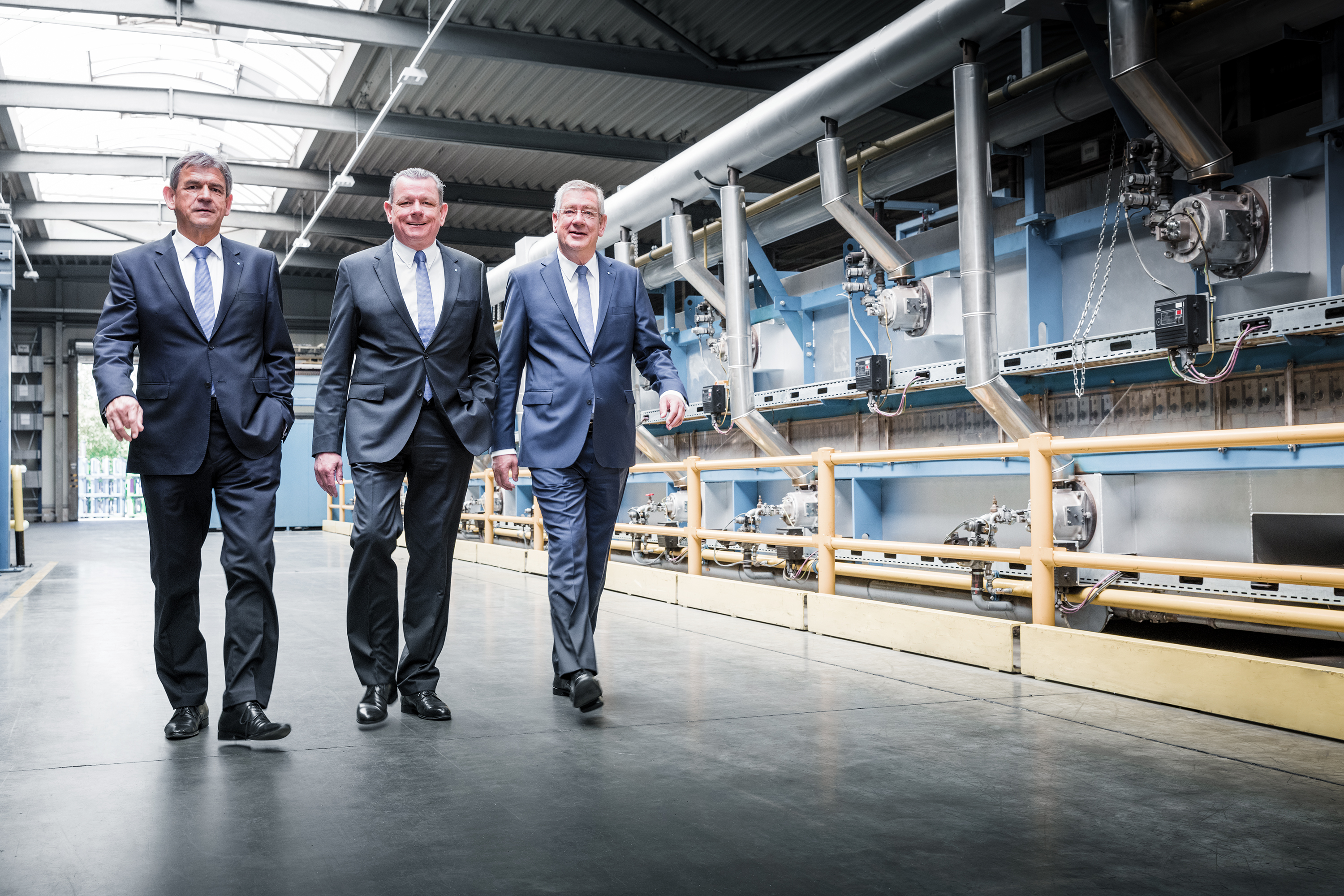

The three owners of the KIRCHHOFF Group (l. to r.): Dr.-Ing. Jochen F. Kirchhoff, J. Wolfgang Kirchhoff, Arndt G. Kirchhoff

KNOWLEDGE.VALUES.CHANGE.

Today's KIRCHHOFF Group consists of four divisions: KIRCHHOFF Automotive, KIRCHHOFF Ecotec, KIRCHHOFF Mobility and WITTE Tools. With 55 factories in 4 continents, 2,100 MEUR and more than 12,500 employees, the KIRCHHOFF Group can look back over a heritage going back 230 years while, at the same time, looking forward to continued success in the future and further consolidation of the family concern, in line with its slogan WE.MOVE.FUTURE.